Our Infrastructure

- We have installed a practical infrastructure, which is equipped with all the facilities required for balanced production process. It is apportioned into different sections such as manufacturing, quality control, warehousing & packaging and many more.

- These wings are designed in order to carry out their respective tasks within the stipulated time-frame.

- Our manufacturing unit is the backbone of our firm, which is outfitted with advanced machines and equipment to speed up the production process.

- Furthermore, the finished machinery components are tested on various parameters, at our quality control unit, in order to ensure delivery of defect-less products to our clients.

Our Machines

- Spark Erosion Machines (Edm) Qty: 2

- (EDM) Wire Cut Machine (Make: Japax) Qty: 1

Spark Erosion Machine

EDM include machining of Complex shapes that would otherwise be difficult to produce with conventional cutting tools. Extremely hard material to very close tolerances. Very small work pieces where conventional cutting tools may damage the part from excess cutting tool pressure. There is no direct contact between tool and work piece. Therefore delicate sections and weak materials can be machined without any distortion. A good surface finish can be obtained. Very fine holes can be easily drilled.

Cylindrical Grinding Machines

The cylindrical grinder is responsible for a plethora of innovations and inventions in the progression of science and technology. Any situation in which extremely precise metalworking is required, the cylindrical grinder is able to provide a level of precision unlike any other machine tool. From the automotive industry to military applications, the benefits the cylindrical grinder have given us are immeasurable.

Surface Grinding Machine

Surface grinding is used to produce a smooth finish on flat surfaces. It is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a workpiece, making a face of it flat or smooth. Surface grinding is the most common of the grinding operations. It is a finishing process that uses a rotating abrasive wheel to smooth the flat surface of metallic or nonmetallic materials to give them a more refined look or to attain a desired surface for a functional purpose.

- Cylindrical Grinding Machine (Make: STUDER) QTY: 2

- Cylindrical Grinding Machine (Make: NOLAF) QTY: 2

- Surface Grinding Machine (Make: SEMCO) QTY: 1

Lapping And Polishing Heads With Stands : 3

Profile Projector: 25 TIMES

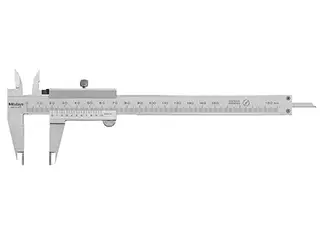

Measuring Instruments

Digimatic Outside Micrometer

Tubular Type Depth Micrometer

Mitutoyo Vernier Caliper

Vernier Height Gage

Dial Indicator

Dial Indicator Micron

Rectangular Gauge Block

Sine Bar on Surface Plate